Industrial Automation

We create systems for the management of production processes. We improve the efficiency, safety and productivity of enterprises. Our specialization is companies in the petrochemical sector. We are well versed in industry specifics, we offer thoughtful and useful solutions.

Most of our projects have been implemented on the basis of SIEMENS. The status of SIЕMENS SOLUTION PARTNER (INDUSTRY, SPECIALIST) confirms the company's high competence in project implementation. Great practical experience and qualifications allow us to create solutions based on any available equipment and maintain the status of one of the largest Russian integrators.

APCS

We cooperate with all leading manufacturers of equipment and software for automation of industrial facilities: Honeywell, Allen-Bradley, Phoenix Contact, Prosoft Systems. We are constantly looking for and studying new products that appear on the market.

What is our job? First of all, we form the concept of the future system, develop the structure. Then we start filling it. From the vast array of elements, we choose the most suitable for solving the task, optimal in cost, tested and create a system from them that meets the individual request of the customer.

There are no standard solutions in the field of automated process control systems. Their development process is creative, interesting, fascinating. And the result is always unique.

HOW WE DO IT?

- Collection of data to study the problem in all its versatility. Each object requires separate research. We know the industry well, so we can easily find a common language with professionals who are daily immersed in their work. We delve into the processes as much as possible and analyze the data to determine how to improve the work.

- Development of a technical solution. A high-quality solution has the following properties: minimally sufficient set of equipment; ease of use and maintenance; 100% compliance with the set goals.

- Discussion and defense of the technical solution. We describe our proposals in detail and give reasoned explanations for them. We explain why this or that system structure was chosen, how redundancy is provided; why devices with specified characteristics are needed; how to ensure the safety of operation; we give an economic rationale for the chosen solutions, etc.

- Development of the project and software. After the approval of the technical solutions, we proceed to the development of the APCS project and writing the software. 19 years of experience has allowed us to develop methods, schemes for implementing projects, as well as collect a large library of our own software solutions. These basic elements are used to create new products, ensure the speed and quality of our work.

- Starting the system. To reduce the time for project implementation, we issue a custom specification for equipment in advance - we can conduct tenders and purchase. In addition, we deliver software that has already been tested on simulators to the facility. Thus, we reduce the work at the facility to a minimum volume.

Stages of complex automation

Pre-project survey of the project

We estimate the actual amount of work, deadlines and cost. We are making changes related to the tightening of the regulatory framework and the shortcomings made in the design of the previous sections of the project documentation.

Development of technical specifications

We determine the list of technical requirements for design. As a result, we get a detailed technical task for the project implementation.

Development of design and working documentation

We draw up technical solutions in the form of drawings and working documents. We reduce the time for developing documentation using modern CAD systems (Eplan Electric P8). We leave more time for verification.

Supply of equipment

We audit documentation. The customer receives not just equipment according to the specification, but a guaranteed working solution.

Software Development

The efficiency of even the most modern process control system directly depends on the quality of the software. Our software development department employs certified programmers and integrators with experience in implementing automation in industrial enterprises. We will prepare your staff to work with the software and hardware complex.

Installation and commissioning

We mount in close cooperation with the design department, which eliminates errors at this stage. Qualification of the personnel allows to lead the complex of installation and commissioning works. Each installation engineer knows the details of the project, is able to see the problems in time and make sure to inform the management. Constant communication between installation engineers and project designers allows us to improve solutions, make them more convenient, simple and reliable.

Warranty and post-warranty service

We will replace defective equipment, adapt and configure the software, taking into account the specifics of production process. We will send specialists to analyze the emerging faults. We can provide technical support during the APCS operation after the warranty period ends.

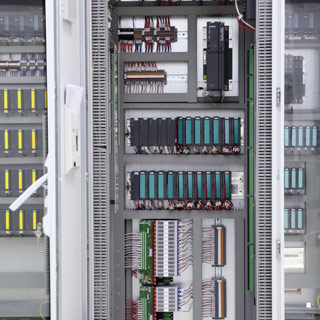

Cabinets, control panels, hardware and software complex "VA2020"

VOLGA-AVTOMATIKA has its own assembly facility and storage facilities (more than 3,000 sq. m.). The workshops are equipped with all the necessary equipment for the manufactory of products that meet international regulatory requirements.

We assemble control panels, cabinets for automation, as well as industrial and technical complexes (PTK) "VA2020", which have a Certificate of Approval of the Type of Measuring Instruments. PTK "VA2020" includes a certain set of equipment, proprietary software, top-level automation elements (workstation of operators, servers, etc.), certified measurement and verification methods.

We can assemble according to customer's projects. Experienced engineers will check the documentation, correct errors if necessary and adapt them to the specifics of your production.

End-to-end control eliminates defects even at high production load. Before shipping of the equipment we test all components, carry out self-contained adjustment and testing.